british anzani archive:

Did you all move across to

Anzani?

Most of the key workers from JARC’s

moved to Anzani’s, and I got the plum

job of running the engine test house.

The outboard engines that made up

the bulk of production at that time con-

sisted of the tiny Pilot dinghy motor,

which were produced in batches of 30,

all the work of a single fitter! I could

test run 9 of these at a time, in our long

tank.

The 4 hp Super Single was in

continuous production at the rate of 9 a

day, and was the best selling product. Three men were involved in the

assembly. One did the ‘power head’ (engine), another the underwater unit and

leg, whilst the third member of the team united all the sub assemblies and got it

ready to run. I tested these, six at a time.

The Unitwins both 10 and 15 bhp were in very limited production, and these

could only be run individually. These were built in much the same manner as

the ‘Super’s’. There were no electric start outboards at that time. Alas, I had no

involvement with the hydroplane racing engines. These received only the

personal attention of Charles Harrison and assembly shop foreman Jock

Edwards, who used the test house at weekends.

Of the air cooled engines, the most popular were the Dynastart equipped car

units, as fitted to the Astra. Although I had a test bed fitted with a Walker fan

brake which could measure BHP, this was not used for the production testing.

The motors were just run in neutral for a while, and the tick-over adjusted! The

same applied to the motorcycle units.

I would also test the Motor Hoe and the Iron Horse as needed! These were both

selling well, but again, they got little more ‘testing’ than did the air cooled

motors. No matter what motor was tested however, it was always run long

enough for the heat to act on the gaskets etc., after which all important bolts

were torqued down and brand new sparking plugs fitted - a nice touch.

Naturally I tested all the Astras too, and was responsible for their final check

out.

How about your old boss?

Poor Richard Christofrides was very unhappy at Anzani’s as control of the car

had passed away from him, and he was very restless. He suggested forming a

brand new company to manufacture the engine that I had originally designed for

the JARC, and so I left Anzani to form RCA with him. We produced that engine

The BAA meets Peter Hogan

Fans of classic British motorbikes

may recall Peter’s name in

connection with the high

performance High-Torque

cylinder heads he designed

for

BSA Bantam

engines

in the early 1950’s. By the late

1950’s he had dev-

eloped his own

motorcycle engine;

the innovative 350cc

RCA engine and when

his Hoganrood

hydroplane outboard

engines won the

British ‘C’ Class National

Hydroplane

Championships in 1960 and 1961 it was yet another

Hogan career milestone. Since then his company in Bodmin making the Dolphin

yacht engine has been keeping him busy until his retirement 15 years ago. In

between times though he was at the Hampton Hill factory of the then flourishing

British Anzani Engineering Company.

Peter, how did you come to be working for Anzani?

In 1954 my brother John and I, had a small engine tuning business specialising

in two stroke engines. We were approached by Richard Christoforides who was

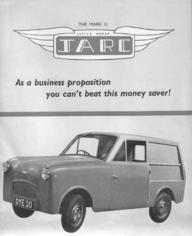

manufacturing an ultra light four wheeled car called the JARC. This was

powered by a 250cc Excelsior Talisman Twin air cooled motorcycle engine, that

was suffering from carburettion problems associated with its use in a car.

The problems were quickly resolved, and I was invited to join the company as

development engineer. The performance of the car however, was very poor (42

mph flat out!) and so I designed a new, more powerful engine especially for it.

Before it could be built however, sales virtually dried up, and it was vital to offer

a radically different new model, to stimulate sales and hopefully, to prevent

bankruptcy. This was powered by the brand new Anzani 328cc blower cooled

light car engine, which Charles Harrison had just evolved from his outboard

engine.

I was able to borrow one of these from the Hampton Hill factory, for

‘experimental purposes’ and was responsible for its installation into the JARC,

and for a number of detail improvements made to it. When Mr. Harrison tried the

final product he was so impressed that he bought the company! (rather like the

Remington Razor story!), and production of the ‘Astra’ (as he renamed it) was

transferred to Hampton Hill.